In internal combustion engines, few components influence performance, oil consumption, and durability as significantly as the piston ring. For the widely used TOYOTA 2E-LU gasoline engine, selecting a high-quality piston ring set is essential to preserving compression efficiency, minimizing blow-by, and maintaining long-term engine reliability.

As an experienced manufacturer of precision engine components, JYPR provides high-grade piston rings engineered specifically to meet the specifications, tolerances, and functional demands of the TOYOTA 2E-LU engine platform.

1. Understanding the Function of Piston Rings in the 2E-LU Engine

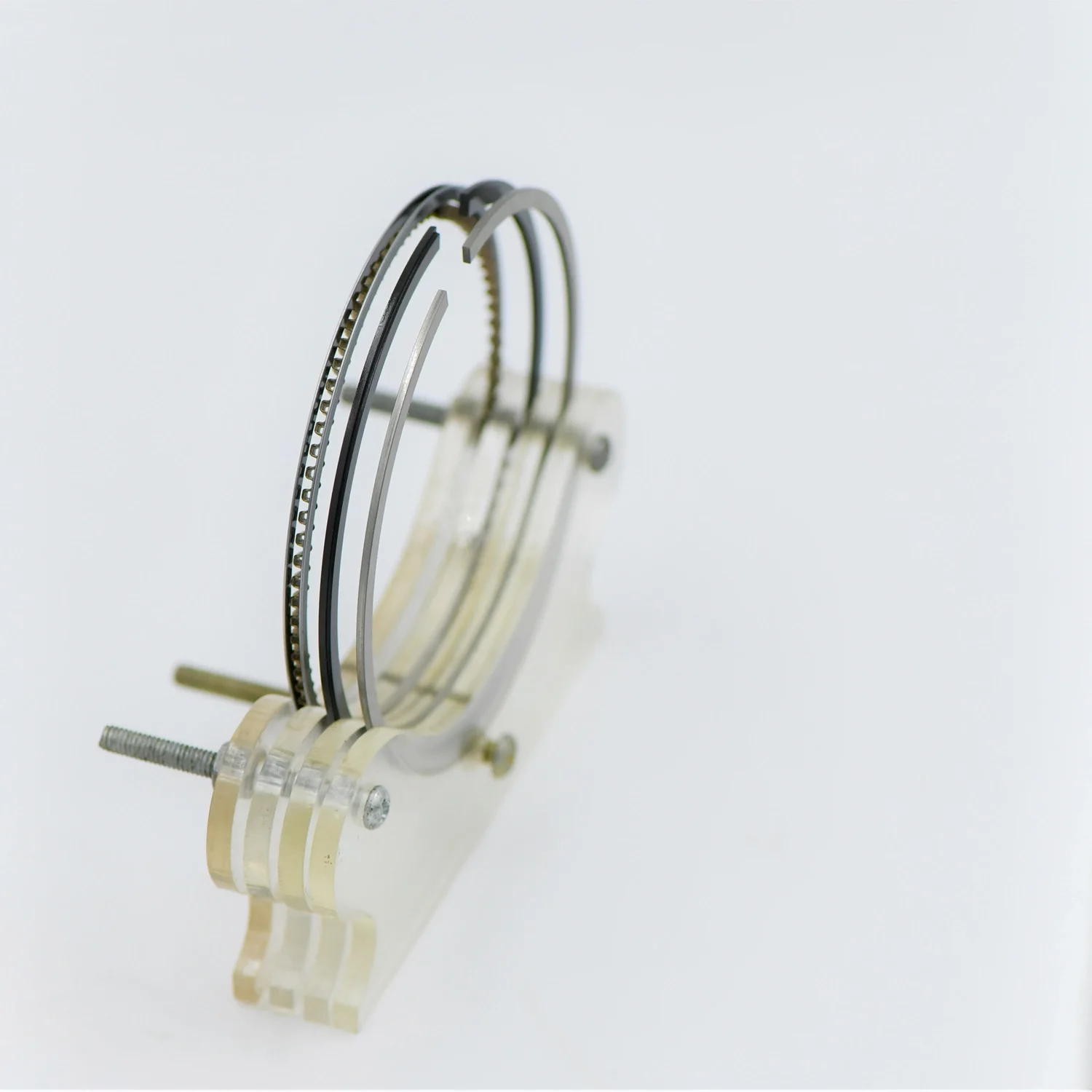

The TOYOTA 2E-LU is a 1.3L inline-four engine known for its durability and fuel efficiency. Its piston ring design directly affects combustion efficiency and lubrication stability. Each piston ring set typically includes:

(1) Compression Ring (Top Ring)

Seals combustion pressure

Maintains cylinder compression

Minimizes blow-by gas

(2) Secondary Ring (Scraper Ring)

Supports compression sealing

Controls oil film thickness

Reduces carbon buildup

(3) Oil Control Ring

Scrapes excess oil from cylinder walls

Ensures proper lubrication without oil burning

High-quality rings fitted to the 2E-LU ensure balanced combustion dynamics and stable performance across the engine’s operating range.

2. Engineering Requirements for a Proper Fit in TOYOTA 2E-LU Engines

A piston ring must match strict tolerances to achieve proper function. The 2E-LU engine requires precise specifications in:

• Ring Diameter and Thickness

Accurate radial and axial dimensions ensure superior fitment without cylinder scoring or excessive friction.

• End Gap Tolerance

Correct end gap maintains thermal expansion capability while sealing combustion gases effectively.

• Ring Groove Clearance

Precision machining prevents ring flutter, reduces wear, and improves sealing stability.

• Surface Coating and Hardness

To withstand high temperatures and abrasives, high-quality rings often use:

Chromium plating

Molybdenum (Mo) spray coating

Nitriding processes

JYPR manufactures piston rings following controlled machining and finishing processes, ensuring perfect compatibility with OEM-grade requirements.

3. Material Technologies Behind High-Quality Piston Rings

For the TOYOTA 2E-LU engine, longevity and high-temperature stability are essential. Premium piston rings use carefully selected materials, such as:

• Ductile Cast Iron

High strength, excellent elasticity, and good thermal tolerance.

• Alloy Cast Iron

Enhanced wear resistance for extended service life.

• Steel Rings (Advanced Options)

Superior fatigue resistance and better sealing at high RPM.

The material choice significantly affects oil control, friction behavior, and resistance to micro-welding under extreme heat.

JYPR incorporates metallurgical testing, controlled cooling, and precise alloy formulation to manufacture rings that withstand long-term operation in harsh environments.

4. Performance Characteristics of High-Quality Fit for TOYOTA 2E-LU Piston Rings

When engineered correctly, piston rings deliver measurable improvements:

(1) Enhanced Compression Sealing

Prevents power loss, stabilizes idle, and improves fuel efficiency.

(2) Reduced Oil Consumption

Precise oil control ring geometry reduces oil burning and smoke emissions.

(3) Lower Friction Coefficients

Improves engine responsiveness, reduces heat generation, and extends engine life.

(4) High Wear Resistance

Advanced coatings reduce abrasion from contaminants and carbon deposits.

(5) Consistent Long-Term Performance

Precision machining ensures minimal ring groove wear and stable cylinder sealing.

JYPR’s TOYOTA 2E-LU piston rings are validated through load testing, thermal cycling, and durability simulations.

5. The Manufacturing Advantages of JYPR

JYPR’s production systems incorporate:

-

CNC-controlled ring turning and finishing

-

Automated end-gap sizing

-

Precision honing for ring face profile control

-

Coating application using thermal spray or galvanic processes

-

100% dimensional inspection

-

Hardness and microstructure testing

This ensures that each ring meets OEM-level fitment accuracy and long-term reliability for TOYOTA 2E-LU engines.

6. Installation Considerations and Best Practices

Using a high-quality ring set is only part of the equation; proper installation determines long-term performance.

Key Guidelines

-

Verify cylinder taper and out-of-round tolerances

-

Measure ring end gap inside the cylinder bore

-

Align ring positions according to TOYOTA service manual

-

Lubricate ring and grooves before assembly

-

Avoid compressing rings excessively during installation

Engineers and technicians using JYPR piston rings benefit from consistent fit, facilitating streamlined installation and reduced rework time.

Conclusion: Reliable Performance Starts with Precision Components

High-quality piston rings play a critical role in sustaining the performance of TOYOTA 2E-LU engines. With engineered materials, precise tolerances, and advanced coatings, JYPR delivers piston rings that ensure optimal sealing, extended durability, and improved engine efficiency.

For OEM replacement, remanufacturing, or performance enhancement, choosing a high quality Fit for TOYOTA 2E-LU piston ring from JYPR guarantees reliability that stands the test of time.

https://www.jy-pr.com/high-performance-sealing-for-toyota-piston-ring-why-quality-matters.html

Comments (0)