In the rapidly evolving world of packaging technology, intelligent solutions are becoming increasingly crucial for enhancing efficiency, accuracy, and sustainability. Among these solutions, the SANTUO carton sealing labeling machine stands out as a versatile and reliable tool in the packaging industry. Incorporating advanced sensors and control systems, these machines offer precision in placement and reliable performance, contributing to overall operational excellence and meeting the growing demands of today's fast-paced market.

Compatibility and Flexibility

Versatile for Various Product Specifications

One of the most notable features of the carton sealing labeling machine is its exceptional compatibility with a wide range of product specifications. This equipment is designed to adapt to different sizes, shapes, and types of cartons without the need for extensive modifications. Switching production from one product to another merely requires simple adjustments. These adjustments are facilitated by marked scale rulers on the adjustment parts, ensuring precision and convenience during the changeover process.

This flexibility is a game-changer for manufacturers who handle diverse product lines. It eliminates the need for multiple machines or time-consuming mold replacements, thereby streamlining production workflows and reducing downtime.

Labeling Mechanism: Precision and Efficiency

Emery-Coated Active Roller and Adaptive Pressure Roller

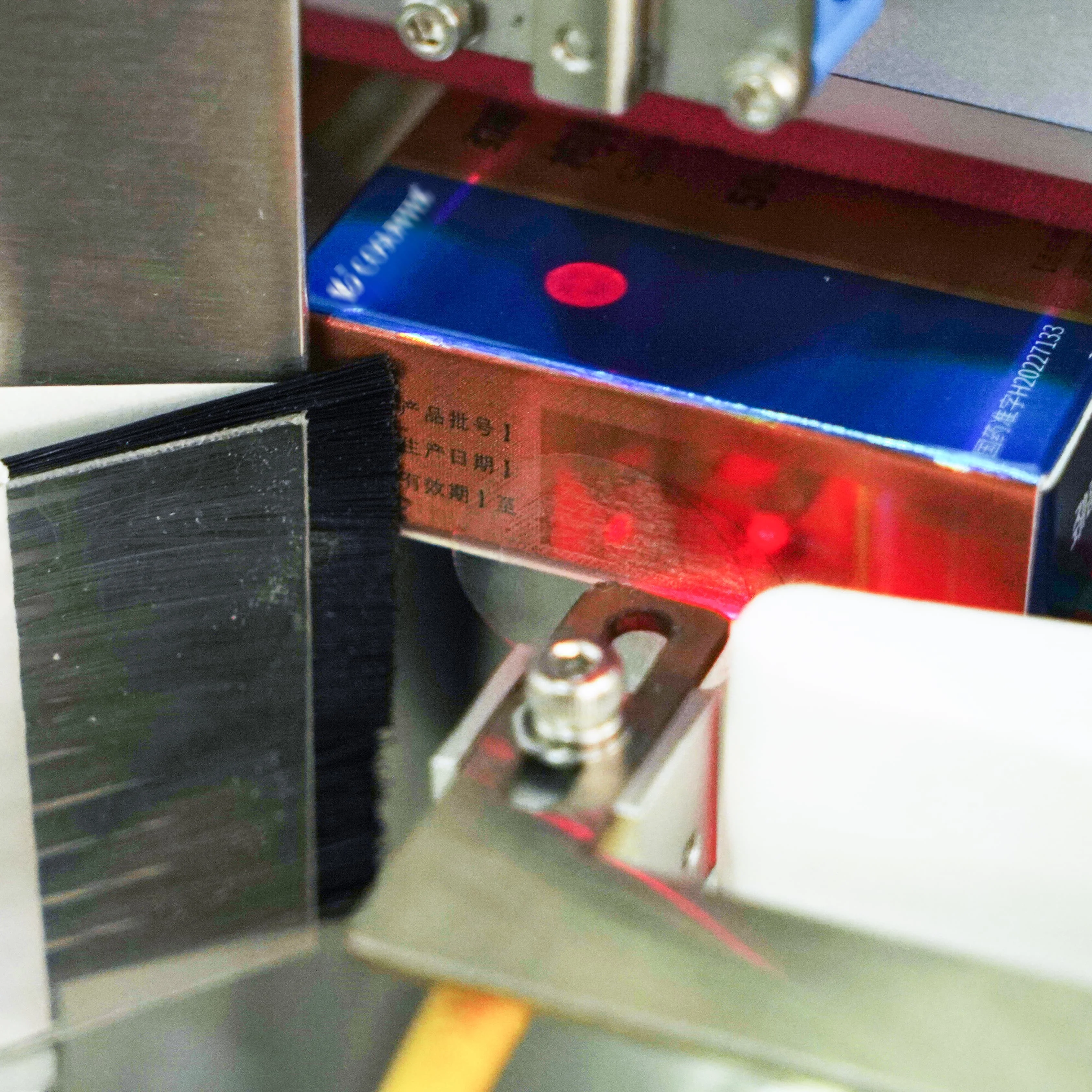

At the heart of the carton sealing labeling machine lies its sophisticated labeling drive. This system utilizes an emery-coated active roller, which provides superior grip and accuracy when applying labels to cartons. The emery coating ensures that the roller maintains a consistent and reliable contact with the label material, preventing slippage and ensuring precise placement.

Complementing the active roller is an adaptive rubber pressure roller. This roller adjusts dynamically to accommodate variations in carton thickness and surface textures. Its flexibility ensures that labels are applied evenly and securely, regardless of the carton's physical characteristics.

This labeling mechanism not only enhances the aesthetics of the packaged products but also plays a crucial role in brand identification, traceability, and compliance with regulatory requirements.

Adaptive Design: Handling Height Deviations

Elastic Top Belt Structure

Another innovative feature of the carton sealing labeling machine is its elastic top belt design. This structure is specifically engineered to accommodate products with varying height deviations. The elastic belt ensures that cartons of different heights can pass through the machine smoothly without affecting the clamping force on adjacent products.

This adaptability is particularly beneficial in environments where product dimensions may fluctuate due to variations in manufacturing processes or raw materials. By maintaining consistent clamping force, the machine minimizes the risk of damage to the cartons and ensures that labels are applied correctly every time.

Robust Construction: Durability and Compliance

High-Quality Materials for Longevity

The main body and key mechanisms of the carton sealing labeling machine are constructed from high-quality stainless steel and aluminum alloy materials. These materials are renowned for their durability, corrosion resistance, and ability to withstand extreme operating conditions.

Stainless steel, in particular, is chosen for its resistance to rust and contamination, making it ideal for applications in the food and pharmaceutical industries. Aluminum alloy, on the other hand, provides a lightweight yet strong framework that enhances the machine's overall stability and precision.

Meeting GMP Standards

The robust construction of the carton sealing labeling machine also ensures compliance with Good Manufacturing Practice (GMP) standards. These standards are crucial for maintaining hygiene, quality, and safety in manufacturing processes. By utilizing materials and designs that meet or exceed GMP requirements, the machine contributes to the overall integrity and reliability of the packaged products.

Conclusion

The carton sealing labeling machine is a testament to the advancements in intelligent packaging solutions. Its compatibility with various product specifications, sophisticated labeling mechanism, adaptive design for handling height deviations, and robust construction make it an indispensable tool in modern manufacturing environments.

As the packaging industry continues to evolve, the carton sealing labeling machine will undoubtedly play a pivotal role in driving efficiency, accuracy, and compliance. By leveraging its core technologies, manufacturers can stay ahead of the competition and meet the ever-growing demands of consumers and regulators.

In conclusion, the carton sealing labeling machine represents the pinnacle of intelligent packaging solutions, combining versatility, precision, adaptability, and durability to revolutionize the packaging industry.

Comments (0)