In this piece, we will go over the how, or more specifically, the functioning of each of the six different kinds of viscometers that are currently on the market. These are the instruments that measure the thickness of a liquid. Viscosity is something that can be measured with these devices. This list does not contain any viscometers, which are instruments that can be useful in a variety of industrial processes. This list does not include any of these viscometers in any way, shape, or form. There is simply no place for them here.

#1 — Orifice viscometers

A cup with a hole in it that has been cut specifically for the purpose of serving as an orifice in an orifice viscometer is the primary component of the device. When discussing the consistency of a liquid, the term "cup seconds" refers to the amount of time needed to completely deplete the contents of a single cup. This period of time is counted and served as the standard for the viscosity measurement unit. Another reason for their widespread use is that orifice viscometers are not prohibitively expensive to purchase. They are uncomplicated and simple to use; they consist of a glass tube in the shape of a U that holds two bulbs, one of which is positioned higher than the other. They are simple. The U-shaped glass tube is what gives them their distinctive appearance.

The viscometers that have falling pistons are the third type of instrument in this category.

Austin Norcross is credited with the invention of the falling piston viscometer on Wikipedia. Citation neededNeeds additional citationsThis is the case as it is generally believed that Austin Norcross was the first person to come up with the idea for the instrument. They function by drawing the fluid being measured into the piston cylinder while the piston is raised; the amount of time it takes for the piston to fall (measured in time-of-fall seconds) due to the resistance of the fluid is used to determine viscosity. Case in point: the viscosity of a liquid can be determined by its time-of-fall seconds. As an illustration, the number of seconds it takes for a liquid to fall to the ground can be used to calculate its viscosity. Viscometers that make use of a falling piston are not only straightforward in their operation and straightforward in their maintenance, but they also have an exceptionally long lifespan.

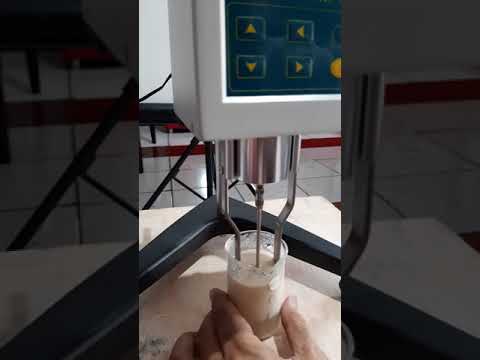

#4 — Rotational viscometers

One can determine the viscosity of a fluid by first inserting a turning spindle into the fluid that is being tested, and then using a rotational viscometer to measure the viscosity of the fluid. This will give one an idea of how viscous the fluid is. Rotational viscometers base their readings on the shear stress that is present within the fluid that is being measured because this is what the viscometer is designed to measure. Because of this, we can be certain that the readings are reliable. The amount of power, or torque, that is needed to turn the spindle can be taken as an indication of the viscosity of the fluid in question.

#5 — Falling ball viscometers

The results that can be obtained from viscometers that utilize falling balls as opposed to viscometers that utilize falling pistons are capable of producing the same results. This is the case even though the two types of viscometers work in opposite ways. Assuming that the dimensions of the ball have already been determined, the viscosity of the fluid can be determined by timing how long it takes the ball (again, in terms of time-of-fall seconds) to fall through the fluid while being subjected to the force of gravity. This can be done by timing how long it takes the ball to fall through the fluid while being subjected to the force of gravity. This can be accomplished by timing the amount of time it takes for the ball to fall through the fluid while being subjected to the force of gravity. There is a broad spectrum of resistance to vibrations offered by various types of fluids, and this spectrum is directly proportional to the viscosity of the fluid. This range of resistance is directly proportional to the viscosity of the fluid. This resistance can be interpreted in the same way as a spectrum. These two standardized units of measurement are connected to the same overarching principle that underlies their relationship to one another. When this stage of the process has been finished, the amount of time that is required for the fluid to pass through the marks will be determined and measured. The kinematic viscosity of the fluid can then be calculated by multiplying this amount of time by an instrument constant after the calculation has been completed. When compared to the density of the fluid, which has an inverse correlation with the amount of time it takes for the fluid to move through the capillary tube, the dynamic viscosity of the fluid does, however, have a direct correlation with the amount of time it takes for the fluid to move through the capillary tube. A flow cup viscometer, also known as an orifice type viscometer, is the type of instrument that is depicted in Figure 2B.

This instrument measures the viscosity of a fluid. Another uncomplicated choice for a capillary digital viscosity meter is the one that is depicted here, with its configuration being the focus of the discussion. The inaccuracy of these instruments is caused by the fact that they are unable to keep a constant pressure on the orifice of the measurement device. This prevents accurate readings from being obtained. Even though they are not only inexpensive but also user-friendly and adaptable, the instruments' lack of precision is a direct result of this, and it is unfortunate because the instruments are otherwise quite flexible and user-friendly. Because of this, it is possible to use pressurized versions of these viscometers in order to measure fluids with a viscosity that is extremely high. Cause and effectWhen in their pressurized forms, these viscometers are also able to function normally despite being subjected to very high pressures because they are in their pressurized states. Forward motion is an appropriate descriptor for the movement of the fluid in both of these scenarios.

A horizontal tube that is fed by a pressurized tank is used in tube viscometers, which are in the same category as capillary viscometers and are used to determine the viscosity of a substance. Tube viscometers belong to the same category as capillary viscometers. A capillary digital viscosity meter is another name for this particular variety of viscometer.2As the tube travels through the instrument, these devices take readings of the pressure at a number of points along its length at various locations along the instrument. This is because despite their low cost, they offer a high level of accuracy in their results.

Comments (0)